Tuesday, December 9, 2014

Why Would Anyone Build a Boat?

Why would anyone build a boat? What kind of question is that for a boat designer to ask? I ask it because there are so many people who ask it in all seriousness. They ask it because they really can't understand why anybody would build a boat instead of buying one. There are so many boats out there that are available and can be acquired with so much less effort, new boats, good used boats, boats that have been damaged in weather events, tired boats that can be rejuvenated and almost dead boats that can be resuscitated.

There is no single answer to that question, there are many reasons why people build boats for themselves and each builder no doubt has a bunch of these reasons rolled up inside whatever it is that drives him to build his boat.

A reason that is common to all of the builders is passion. They have a passion to create a boat, to create something that would never have existed were it not for them and their desire to do this. Having been there myself many times, I can attest to the fantastic feelings that flood through when we first put that new boat into the water and then to give it life by hoisting sail or opening the throttle for the first time. If you think about how wonderful you felt when you first used a new boat that you had bought, doing the same in a boat that you have created with your own hands intensifies those feelings in ways that can't be described.

It is that passion that also drives many of the decisions that are made during the build project. It drives them to do quality work because they want to feel pride in the final product. They want their creation to show well when seen by others, to be seen as a thing of beauty. Those who have never thought to build a boat themselves look at it and say "Wow, did you build that?".

Financial restraints are behind many amateur boatbuilding projects. If you need or want a new (as in not pre-owned) boat that costs double the money that you can afford to put into it, then the only route to get it is to build it yourself. I have never calculated ahead of my boatbuilding projects how much they are going to cost. Each time I have just dived right in and started, then kept going to the end. That was when I found out what the total cost was and was able to compare with what it would have cost me to buy an equivalent new pop-out production boat. Each time the cost of my fully-equipped boat was around 45% of the cost of a base-package for a production boat of similar size and concept.

Those who don't get it say "It cost you a lot more, you haven't priced in your labour hours, which must be priced at your professional rate of pay". No, we don't price our labour into the project and no, we should not price it at the rate that we receive in our paying jobs, whatever they may be. The project serves as a hobby, as recreation that helps us to recover from a tough week working for someone else. It helps to keep us motivated and able to take on the world. The alternative of working very extended hours at our paying jobs to generate the funds to pay someone else to build our boat brings with it a risk of getting burned out in the process.

Many people who build big boats for long distance cruising want to build it themselves to give them confidence in the strength of the boat. They know that they will be sailing their boat on very remote waters, far from rescue services and possibly with their beloved family aboard. The safety of all depends on the quality of the build and they don't want to leave that to people whom they don't know. They have vested interest in doing everything in the best manner possible, so they want to do it themselves. In the process they garner the side benefit of knowing intimately how the boat works, where all of the important parts are, how to get to every seacock or filter in a hurry when dictated by some emergency that may develop onboard. They know exactly how to repair everything onboard because they installed it in the first place. They are likely to lay out all aspects in a very sensible and logical manner because they will have to maintain it themselves. At sea in a storm is not the best time to be trying to track down plumbing or electrical faults in systems that are overly obscure because the person who installed them before the hull liners or lockers were installed didn't consider the problems of working on them in the completed boat.

Others build their own boats because they want something different, a boat that will stand out from the crowd on marinas, at sea and in distant anchorages. They add personal styling features to fit their own characters and they choose joinery detailing such as is not available from production boatbuilders.

Some people choose to build a boat purely for the hobby benefit. They enjoy the build more than using the boat, so the project will be drawn out interminably. They produce exceptional quality in the process but will probably sell the boat when completed or soon after.

It has been said many times that the happiest days of a boatowner's life are when he buys and when he sells the boat. The exception to that cliche is the boatowner who has built his boat himself. There is so much of the builder wrapped up in that boat, in the form of blood, sweat and tears, to say nothing of chunks of skin and body hair, that he and the boat have an affinity and intimacy that is unknown to those who buy their boats. I have felt very sad when selling each of the boats that I have built, far from the happiest days of my life.

It has also been said many times that boatbuilding is a disease and when you have had it, you will experience periodic relapses. I have to agree with this one, I have had numerous relapses. I can't say that I have suffered relapses, as would apply to most diseases, I have enjoyed those relapses too much to convince my wife that I have suffered in any way. And this is the way that most amateur boatbuilders feel. Visit any of the many boat shows that cater for amateur boatbuilders and you will see for yourself how much they love what they do and just how much passion they build into their projects.

To see our range of designs, for amateur or professional boatbuilding, please go to http://dixdesign.com.

Read More..

There is no single answer to that question, there are many reasons why people build boats for themselves and each builder no doubt has a bunch of these reasons rolled up inside whatever it is that drives him to build his boat.

A reason that is common to all of the builders is passion. They have a passion to create a boat, to create something that would never have existed were it not for them and their desire to do this. Having been there myself many times, I can attest to the fantastic feelings that flood through when we first put that new boat into the water and then to give it life by hoisting sail or opening the throttle for the first time. If you think about how wonderful you felt when you first used a new boat that you had bought, doing the same in a boat that you have created with your own hands intensifies those feelings in ways that can't be described.

|

| Petr Muzik built his Shearwater 39 then circumnavigated in his 70's. |

Financial restraints are behind many amateur boatbuilding projects. If you need or want a new (as in not pre-owned) boat that costs double the money that you can afford to put into it, then the only route to get it is to build it yourself. I have never calculated ahead of my boatbuilding projects how much they are going to cost. Each time I have just dived right in and started, then kept going to the end. That was when I found out what the total cost was and was able to compare with what it would have cost me to buy an equivalent new pop-out production boat. Each time the cost of my fully-equipped boat was around 45% of the cost of a base-package for a production boat of similar size and concept.

Those who don't get it say "It cost you a lot more, you haven't priced in your labour hours, which must be priced at your professional rate of pay". No, we don't price our labour into the project and no, we should not price it at the rate that we receive in our paying jobs, whatever they may be. The project serves as a hobby, as recreation that helps us to recover from a tough week working for someone else. It helps to keep us motivated and able to take on the world. The alternative of working very extended hours at our paying jobs to generate the funds to pay someone else to build our boat brings with it a risk of getting burned out in the process.

uqcshlukaxroqdfv7926%3Dot)35%3B7%3D626%3D425%3DXROQDF)28598%2B4873259ot1lsi.jpg) |

| Andrew Morkel built his Argie 15. Now he and his family are learning to sail in it. |

Others build their own boats because they want something different, a boat that will stand out from the crowd on marinas, at sea and in distant anchorages. They add personal styling features to fit their own characters and they choose joinery detailing such as is not available from production boatbuilders.

|

| Sergey Federov built his Hout Bay 33 to a very high standard. |

It has been said many times that the happiest days of a boatowner's life are when he buys and when he sells the boat. The exception to that cliche is the boatowner who has built his boat himself. There is so much of the builder wrapped up in that boat, in the form of blood, sweat and tears, to say nothing of chunks of skin and body hair, that he and the boat have an affinity and intimacy that is unknown to those who buy their boats. I have felt very sad when selling each of the boats that I have built, far from the happiest days of my life.

It has also been said many times that boatbuilding is a disease and when you have had it, you will experience periodic relapses. I have to agree with this one, I have had numerous relapses. I can't say that I have suffered relapses, as would apply to most diseases, I have enjoyed those relapses too much to convince my wife that I have suffered in any way. And this is the way that most amateur boatbuilders feel. Visit any of the many boat shows that cater for amateur boatbuilders and you will see for yourself how much they love what they do and just how much passion they build into their projects.

To see our range of designs, for amateur or professional boatbuilding, please go to http://dixdesign.com.

Thursday, December 4, 2014

Hull Turning Methods

I have shown a few projects in this blog over the past few months with the hulls being turned using different methods. The bigger the boat the more critical this operation is. The risks of damage to property and injury to people increase exponentially as the boat becomes more bulky and increases in weight. Imagine the difference between turning over a plywood hull that is 6.4m (21ft) long, 2.4m (7'10") wide, 1.2mm (3'11") deep and weighing 200kg (440lb) or a 50% scaled up version of the same hull. At 9.6m (31'6") long, 3.6m (11'10") beam and 1.8m (5'11") deep, it will weigh 675kg (1488lb).

It has only increased 50% in all directions but the weight is more than 3x that of the smaller boat. The bulk becomes more difficult to manage and the weight to lift and lower becomes a major factor. If, at the same time as increasing the size, you also change to steel as the construction material, that same size hull could weigh 2500-2750kg (5500-6000lb). Now you are talking about some serious loads that can get out of control, yet the boat is still only 50% bigger in each direction.

Those smaller projects are easily turned over by hand, with friends and neighbours supplying the motive power and the boat having a soft landing on tyres or some other cushioning material. Years ago a client of mine in South Africa turned his 32ft hull by himself. He jacked it up on one side until it reached the balance point, then let gravity take it the rest of the way. It fell against a young tree, then slid down the tree and came to rest flat on the ground. Luckily his hull was relatively undamaged but the tree didn't survive the experience.

There are many ways to turn a hull but that is not one of them. I have a whole chapter on this subject in my book "Shaped by Wind and Wave", to give guidance on how to safely turn your hull. The two Didi 950 hulls that were turned recently in USA and Australia both used the spit-roast method. For each of my own big boats I have used a chain block to do the work, another of the methods explained in the book.

The book can be ordered either as a paperback or as digital for reading on whatever screen device suits you.

To see our range of designs, go to http://dixdesign.com/.

Read More..

It has only increased 50% in all directions but the weight is more than 3x that of the smaller boat. The bulk becomes more difficult to manage and the weight to lift and lower becomes a major factor. If, at the same time as increasing the size, you also change to steel as the construction material, that same size hull could weigh 2500-2750kg (5500-6000lb). Now you are talking about some serious loads that can get out of control, yet the boat is still only 50% bigger in each direction.

Those smaller projects are easily turned over by hand, with friends and neighbours supplying the motive power and the boat having a soft landing on tyres or some other cushioning material. Years ago a client of mine in South Africa turned his 32ft hull by himself. He jacked it up on one side until it reached the balance point, then let gravity take it the rest of the way. It fell against a young tree, then slid down the tree and came to rest flat on the ground. Luckily his hull was relatively undamaged but the tree didn't survive the experience.

There are many ways to turn a hull but that is not one of them. I have a whole chapter on this subject in my book "Shaped by Wind and Wave", to give guidance on how to safely turn your hull. The two Didi 950 hulls that were turned recently in USA and Australia both used the spit-roast method. For each of my own big boats I have used a chain block to do the work, another of the methods explained in the book.

|

| Turning the 38ft "Black Cat" using a chain block on a scaffold tower. |

To see our range of designs, go to http://dixdesign.com/.

Wednesday, December 3, 2014

Of Camels, Boats, Dunes and Things

We all learn in school about the "ship of the desert", the much maligned camel. These animals and their owners are totally adapted to living on and cruising the undulating surface of the desert. We also know of the traditional boats of the Arab world, the dhows that are seen in both power and sail versions. These are very seaworthy boats and have done extensive voyages.

Not heard of nearly as often in that part of the world is the construction of a modern high performance yacht. Such a construction project is the Didi Mini Mk3 of Hugo Vanderschaegh, proceeding apace in Dubai. This is a Mini 650 racer that is built from plywood. Designed primarily for amateur builders, this one is being built by professionals. The photos below show the hull with all flat sheets fitted and the radius skin starting, through to hull turning.

This boat is being built from a CNC kit that was supplied by our Cape Town kit supplier, CKD Boats. They are able to supply kits for most of our radius chine plywood designs as well as the classically-styled lapstrake designs.

They turned Hugo's hull right-way-up last week and recorded it on time-lapse video. They accomplished it with plenty of helping hands and no mechanical equipment. This is a wide boat, at 3m beam, so it towers above the men providing the muscle power. It worked in their situation with lots of hands but "don't try this at home". For the average builder it is better and safer to use mechanical equipment to raise one side under control then lower it again on the other side.

You can see more of his Didi Mini Mk3 project on Hugo's website and follow future progress. Also visit our website at http://dixdesign.com/ to read more about our range of designs and available kits for our plywood boats.

Read More..

Not heard of nearly as often in that part of the world is the construction of a modern high performance yacht. Such a construction project is the Didi Mini Mk3 of Hugo Vanderschaegh, proceeding apace in Dubai. This is a Mini 650 racer that is built from plywood. Designed primarily for amateur builders, this one is being built by professionals. The photos below show the hull with all flat sheets fitted and the radius skin starting, through to hull turning.

This boat is being built from a CNC kit that was supplied by our Cape Town kit supplier, CKD Boats. They are able to supply kits for most of our radius chine plywood designs as well as the classically-styled lapstrake designs.

|

| Didi Mini Mk3, flat panels completed and 1st layer of radius starting. |

|

| 2nd layer of radius almost finished. |

|

| Didi Mini Mk3 hull skin completed. |

|

| Clean and powerful stern sections. |

|

| Completed hull ready to turn over. |

You can see more of his Didi Mini Mk3 project on Hugo's website and follow future progress. Also visit our website at http://dixdesign.com/ to read more about our range of designs and available kits for our plywood boats.

Saturday, November 29, 2014

Dudley Dix Yacht Design Calendar 2015

Our 2015 calendar is ready and our first stocks arrived today. If you are a lover of our designs then this calendar will be a great piece of art to fill that empty space on the wall of your office, home or workshop.

The cover photo (also November) is a beautiful sunset photo sent by Phil Semenov of his self-built Didi 34, sailing in Ukraine.

Here are a few other sample pages.

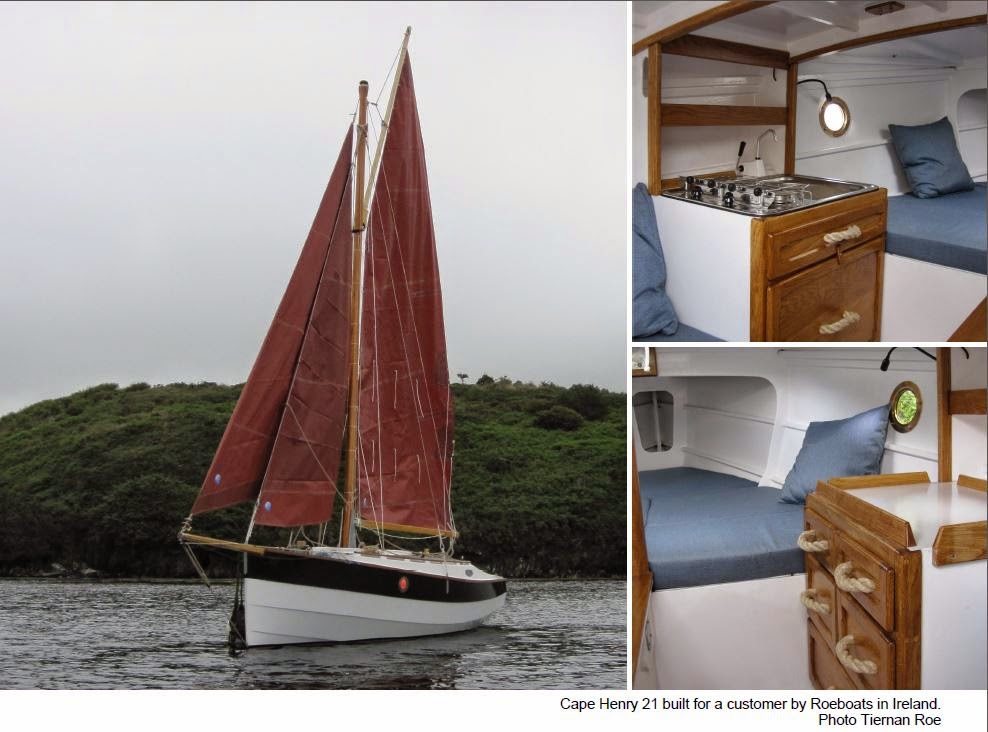

June is a collage of photos showing the Cape Henry 21 built by Roeboats of Co Cork in Ireland. They used some interesting and very pretty detailing in this boat, built for a customer from France.

August is the Didi Sport 15 project of Hunter Gall in Virginia Beach, USA. She is named "Scallywag", which is what Hunter's grandfather called him as a child. The main photo is an interesting view during construction and has a somewhat spiritual feel.

December is Petr Muzik's Shearwater 39 "Shoestring III" sailing in St Helena Bay, South Africa. Petr circumnavigated on this boat when well into his seventies.

Order your calendar from our website via the link on our homepage at http://dixdesign.com/ and we will mail it to you.

Alternatively, click here to order from our publisher, Lulu. They will print and ship one copy, or as many as you want, from their closest affiliate to your delivery address.

Either way, get yours now to be ready for January 2015.

If you have one of our boats and would like to see it featured in one of our calendars, please send me some nice high resolution photos of her. The pics need to show her in pretty surroundings or to be interesting in some other way. Now is a good time to start with the 2016 calendar.

And if you want to see more about our designs, please visit our website at http://dixdesign.com/.

Read More..

The cover photo (also November) is a beautiful sunset photo sent by Phil Semenov of his self-built Didi 34, sailing in Ukraine.

Here are a few other sample pages.

June is a collage of photos showing the Cape Henry 21 built by Roeboats of Co Cork in Ireland. They used some interesting and very pretty detailing in this boat, built for a customer from France.

August is the Didi Sport 15 project of Hunter Gall in Virginia Beach, USA. She is named "Scallywag", which is what Hunter's grandfather called him as a child. The main photo is an interesting view during construction and has a somewhat spiritual feel.

December is Petr Muzik's Shearwater 39 "Shoestring III" sailing in St Helena Bay, South Africa. Petr circumnavigated on this boat when well into his seventies.

Order your calendar from our website via the link on our homepage at http://dixdesign.com/ and we will mail it to you.

Alternatively, click here to order from our publisher, Lulu. They will print and ship one copy, or as many as you want, from their closest affiliate to your delivery address.

Either way, get yours now to be ready for January 2015.

If you have one of our boats and would like to see it featured in one of our calendars, please send me some nice high resolution photos of her. The pics need to show her in pretty surroundings or to be interesting in some other way. Now is a good time to start with the 2016 calendar.

And if you want to see more about our designs, please visit our website at http://dixdesign.com/.

Saturday, November 22, 2014

Cape Henry 21 Professional Build in Ireland

Tiernan Roe is a professional boatbuilder in County Cork, Ireland. His company, Roeboats, specialises in building quality wooden boats. Mostly of classic styling, they build for sail, power or rowing. Roeboats recently launched a Cape Henry 21 that they built for a customer from France.Tiernan sent me these photos, which show some interesting details brought into one of our most popular small cruisers.

You can follow the construction of this boat on the Roeboats news blog, from start through to launch.

After launch, Tiernan Roe sent me these comments. "She sails very nicely and I found her easy to single hand from the get go. The interior is pretty snazzy with frame and panel oak fronted drawers and a gas stove with tank fed sink. Also the centreboard was a lot easier to operate than I thought. It's an awkward shape out of the boat to try and move alone."

To see our full range of designs, please visit http://dixdesign.com/

Read More..

|

| Cape Henry 21 ready to get wet. |

|

| Launched in a pretty setting. |

|

| First sail of the new boat. |

|

| The mainsail has still to be fully set up in these photos. |

| |

| Compact sink & cooker unit, neatly executed. |

|

| Other side of the galley. Nice detailing. |

|

| Looking aft from the double forward berth. |

After launch, Tiernan Roe sent me these comments. "She sails very nicely and I found her easy to single hand from the get go. The interior is pretty snazzy with frame and panel oak fronted drawers and a gas stove with tank fed sink. Also the centreboard was a lot easier to operate than I thought. It's an awkward shape out of the boat to try and move alone."

To see our full range of designs, please visit http://dixdesign.com/

Sunday, November 16, 2014

DS15 (Didi Sport 15) Build in South Africa

Until now I have only shown the DS15 prototype, being built in Virginia Beach, USA, by Aussie Hunter Gall. Hunter's project is currently stalled due to circumstances but one of the the other builds is steaming ahead apace. This one is being built by Jim Foot in Port Elizabeth, South Africa. This weekend Jim applied the last coat of epoxy to the outside of his hull and is preparing to paint it.

This series of photos shows the basics of Jim's project up to this stage. This is a radius chine plywood design, with hard chine along the topsides. It is the same family of designs as the Didi Mini Mk3 and Didi 950.

I will show more of Jim Foot's project as it progresses toward launch date. I tend to show the projects for which I receive the best photos, so please send me your best pics if you want to see your project on this blog or the Dudley Dix Yacht Design main website.

Read More..

This series of photos shows the basics of Jim's project up to this stage. This is a radius chine plywood design, with hard chine along the topsides. It is the same family of designs as the Didi Mini Mk3 and Didi 950.

|

| Frames set up on building stocks, with stringers going on. |

|

| Stringers all done and bottom panels fitted. |

|

| Same stage, showing stringers running into forefoot. |

|

| Side panels fitted and first layer of radius progressing. |

|

| Stitch-&-glue detail of topside chine. |

|

| Second layer of radius going over first layer. |

|

| Completed radius chine, running smoothly into flat panels. |

|

| Glass taping centreline seam. Jigsaw joints of bottom panel can be seen. |

|

| Epoxy coatings started. |

|

| Nice finish starting to show. |

|

| Clean stern and nice finish. |

|

| Final coat of epoxy, ready for sanding and painting. |

Tuesday, November 11, 2014

Didi 38 Prototype Birthday

"Black Cat" is the prototype of my Didi 38 design, built in my back garden in Hout Bay, South Africa. She was also the experiment that developed into my radius chine plywood range of designs, all under the Didi name. Today is her birthday, it is 19 years since we launched "Black Cat" at Royal Cape Yacht Club in Cape Town.

Much has happened since then. She has 70 sisters in the water or in build around the world, in the Didi 38/40/40cr design series. She also has hundreds of smaller radius chine plywood monohull sisters being built or in the water, from the Didi Sport 15 through to the Didi 34. She has also spawned catamaran designs in the Dix 470 and DH550.

When I designed her, I did not imagine how popular this construction method would become. The Didi 38 design was for my own use. After that I drew the Didi 34 for a design competition that was run by South African Yachting magazine, now part of Richard Crockett's Sailing for Southern Africa magazine. Since then I have always had at least one other concept waiting in line for me to draw it for this method of construction. Now is no different, I have a commission for a 38ft big sister to the Didi 950 and have many people asking for smaller sisters to the two catamarans, in various sizes. All that I need is the time to draw them.

Happy Birthday "Black Cat", you have been very good to us.

To see more of our designs, go to http://dixdesign.com.

Read More..

|

| Didi 38 "Black Cat" at the start of the 1996 Cape to Rio Race. |

When I designed her, I did not imagine how popular this construction method would become. The Didi 38 design was for my own use. After that I drew the Didi 34 for a design competition that was run by South African Yachting magazine, now part of Richard Crockett's Sailing for Southern Africa magazine. Since then I have always had at least one other concept waiting in line for me to draw it for this method of construction. Now is no different, I have a commission for a 38ft big sister to the Didi 950 and have many people asking for smaller sisters to the two catamarans, in various sizes. All that I need is the time to draw them.

|

| "Black Cat" in Brazil's Bay of Islands. |

To see more of our designs, go to http://dixdesign.com.

Subscribe to:

Posts (Atom)